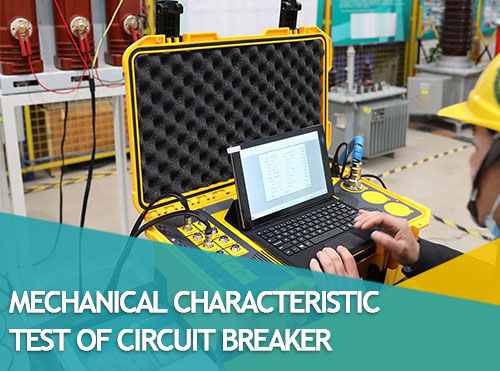

HOT PRODUCTS

HV Hipotwelcome to us

WE OFFER THE BEST QUALITY PRODUCTS

HV Hipot Electric Co., Ltd., located in Wuhan, China, is a professional manufacturer specialized in electrical safety testing equipment, especially high voltage testing equipment since the year of 2003. We TEST for various kinds of electrical products, such as Transformers, Circuit Breakers, Surge Arresters, Generators, Insulators, Cables, Casings, GIS Systems, CT/ PTs, and Relays, etc. Years of experiences and strong R & D supports have made us become a leader in the field of electrical testing.

Operation Video

HV HipotSuccessful Cases

HV Hipot-

Thai and Philippine customers gathered at HV HIPOT for cooperation

Recently, our company ushered in a unique event – Thai customers and Philippine customers gathered in our company to visit! Thai customers have shown strong interest in our ultra-low frequency, local discharge and cable testing equipment, and actively demonstrated their willingness to co...

-

Notice on 2024 Qingming Holiday

HV HIPOT Electric Co., LTD. “Notice on 2024 Qingming Festival holiday ” is as follows; Notice: April 4 (Thursday) to April 6 (Saturday) holiday, a total of 3 days. April 7 (Sunday) work. Please arrange your work and life in advance, civilized and orderly sweep, and green travel.