China High Quality Partial Discharge Test On Transformer Factories – Partial Discharge Online Monitoring System of GIS – HV Hipot

China High Quality Partial Discharge Test On Transformer Factories – Partial Discharge Online Monitoring System of GIS – HV Hipot Detail:

General Information

Gas-insulated metal-enclosed switches (GIS) and gas-insulated metal-enclosed transmission lines (GIL) are one of the most important devices in the power system. They have the dual tasks of control and protection. If they failed during operation and the problem cannot be solved timely,it will cause serious damage to the grid. Partial discharge fault is a common fault type of GIL/GIS. It is necessary to use GIS partial discharge online monitoring and fault location system to perform real-time online monitoring of GIL/GIS partial discharge signals and analyze and process the measured data and real time give comprehensive judgment of insulation status. Then repair schedule can be arranged according to the monitoring results to avoid major grid accidents caused by equipment failure and to ensure the normal operation of the system with minimum maintenance cost.

There are many reasons for the deterioration of the dielectric medium, such as ionization corrosion caused by a strong electric field for a long time, insulation wear caused by mechanical high-frequency vibration, aging decomposition of the medium caused by thermal effects, and moisture insulation. The dielectric medium is degraded, and the performance is degraded so that the dielectric breakdown has a development process, which makes the on-line monitoring of insulation practical and effective. The system uses Smart Quick software developed totally by HVHIPOT. It uses advanced high-speed DSP digital processing technology and software. The processing technology makes our monitoring system fast and accurate, which is the most economical and reliable solution for the online monitoring system of GIS.

Monitoring Principle

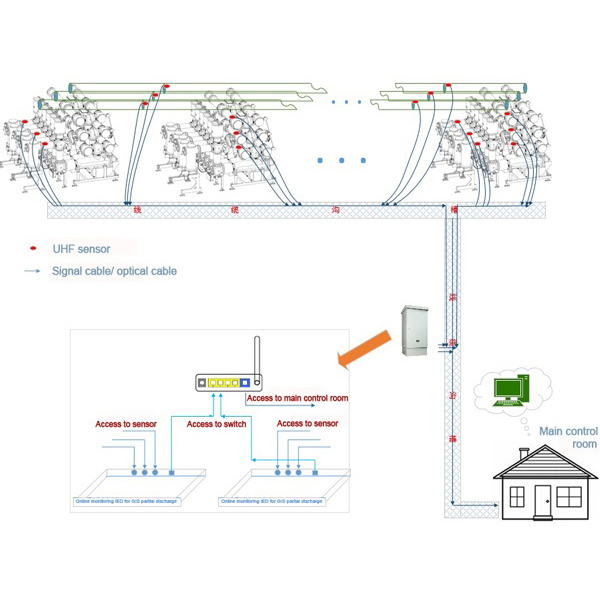

Through installing UHF sensor on the key components of GIL/GIS, to collect 500MHz-1500MHz electromagnetic wave signal excited by the partial discharge of GIL/GIS in real time. It also collects feature quantities such as amplitude (Q), phase (Φ), frequency (N), and cycle sequence (t) of the partial discharge pulse signal that reaches the trigger condition by detection frequency reduction circuit, high speed sampling circuit and data processing buffer circuit. Event files are generated and uploaded to upper computer expert diagnosis system, to perform event map establishment and monitoring equipment insulation state analysis.

UHF PD measurement principle

Install the UHF sensor on the busbar part or GIL. The sensor measurement principle diagram is shown in the above figure. The sensor installation is divided into built-in and external modes. Multiple sensors can be installed on one GIS interval or the whole GIL to achieve effective monitoring of different parts. Anoise sensor is required to acquire the background noise and compare it as a background signal during data analysis.

The installation principle of the UHF partial discharge sensor for GIL is the same as that of the GIS and is arranged according to the distance characteristics of the PD signal propagation. The built-in sensor is installed in the pre-installed way of GIL/GIS production. The sensor arrangement should ensure that the partial discharge occurring at any position inside GIL/GIS can be effectively detected. Under this premise, the sensor should be installed in key components of GIL/GIS, including circuit breakers, disconnectors, voltage transformers, busbars, etc.

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for China High Quality Partial Discharge Test On Transformer Factories – Partial Discharge Online Monitoring System of GIS – HV Hipot , The product will supply to all over the world, such as: Lesotho, Madras, Bolivia, Our company has always insisted on the business principle of "Quality, Honest, and Customer First" by which we have won the trust of clients both from at home and abroad. If you are interested in our products, please do not hesitate to contact us for further information.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.