Prevent Oil Leakage of Oil-immersed Transformer

The oil-immersed transformer oil tank is filled with transformer oil, and the oil-resistant rubber parts are pressurized and sealed by fasteners during assembly. Lack of sealing is the main reason for oil leakage of oil-immersed transformers, so special attention should be paid to the maintenance of oil-immersed transformers.

Check whether the small bolts of the oil-immersed transformer are loose after vibration, and tighten them if they are loose. Tightening should be proper and consistent throughout. Whether the rubber of the oil-immersed transformer is broken or seriously deformed. At this time, when replacing the renewable rubber parts, pay attention to whether their models and specifications are consistent, and keep the sealing surface of the oil-immersed transformer clean.

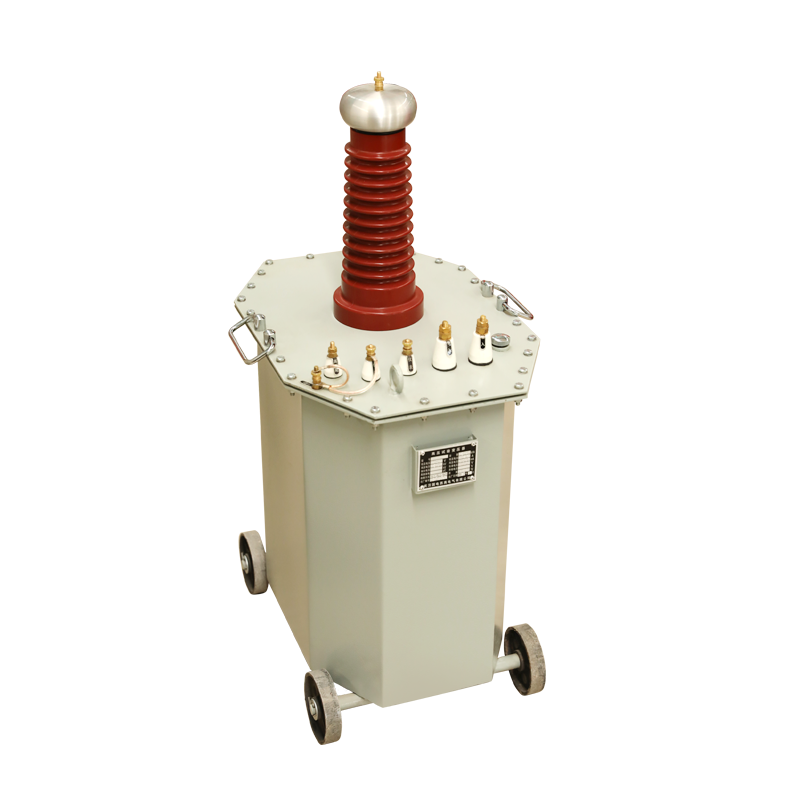

YD series oil-immersed test transformer

Prevent oil-immersed transformers from getting wet

The oil-immersed transformer is a high-voltage equipment, which requires the oil-immersed transformer to maintain good insulation performance. Oil-immersed transformers are very susceptible to moisture. Preventing oil-immersed transformers from getting wet is one of the main measures to maintain transformers.

To this end, users are requested to pay attention to the following:

1. After the oil-immersed transformer is purchased, immediately ask the power supply bureau to do a handover test. Install the dehumidifier immediately. Oil-immersed transformers with a capacity of 100kVA and above are equipped with moisture absorbers. After the oil-immersed transformer is transported to the site, a moisture absorber should be installed immediately to prevent the interior of the oil-immersed transformer from getting damp. Monitor the silica gel in the dehumidifier and replace it as soon as it gets wet. The silica gel in the moisture absorber can absorb moisture and protect the oil-immersed transformer. The color of the silica gel will change when it gets wet, and new dry silica gel should be replaced at this time.

2. When ordering, please pay attention to shorten the storage time of the oil-immersed transformer before power transmission as much as possible. After the oil-immersed transformer is manufactured, it is very vulnerable to moisture during storage. The longer the storage time, the more severe the moisture.

Therefore, a plan should be arranged to shorten the storage time as much as possible. Small oil-immersed transformers with a capacity of 100kVA and below, without moisture absorption devices. The oil in the oil conservator of oil-immersed transformer is easy to get damp, and the oil conservator will accumulate water. If it has been stored for more than six months or put into operation for more than one year without power supply, the oil in the oil conservator of the oil-immersed transformer has been seriously affected by damp.

3. For lifting and transportation, maintenance and refueling, oil drain valve, hoisting iron core, etc. of the oil-immersed transformer, the dirty oil in the oil pillow should be drained through the oil drain plug under the oil-immersed transformer first, and the oil-immersed transformer should be wiped with a dry cloth. The transformer is sealed to prevent the dirty oil in the oil conservator from entering the oil tank of the oil-immersed transformer. During the operation of oil-immersed transformers, we must always pay attention to the changes of oil level, oil temperature, voltage and current. If there is any abnormality, analyze and deal with it in time. When installing an oil-immersed transformer, it is strictly forbidden to use aluminum stranded wires, aluminum busbars, etc.

Post time: Jun-25-2023